储气罐机器人生产线

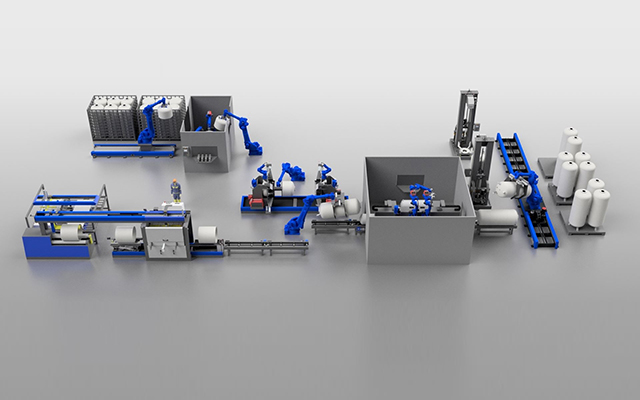

The production line for gas tank robots is a highly sophisticated and meticulously designed system that integrates advanced robotics, automation, and precision engineering to manufacture robotic systems specifically designed for handling and inspecting gas tanks. This production line is a testament to modern manufacturing capabilities, ensuring efficiency, accuracy, and safety throughout the entire process.The production process begins with the design and prototyping phase, where engineers utilize cutting-edge CAD (Computer-Aided Design) software to create detailed blueprints of the gas tank robots. These designs are optimized for functionality, durability, and ease of maintenance. Once the design is finalized, the production line transitions to the fabrication stage. Here, high-precision CNC (Computer Numerical Control) machines are employed to manufacture the robot's structural components, ensuring that each part meets stringent quality standards.The assembly phase is where the production line truly showcases its automation prowess. Robotic arms, guided by advanced AI algorithms, meticulously assemble the various components of the gas tank robot. These robots are equipped with sensors and cameras to ensure precise alignment and correct installation of each part. The assembly process is closely monitored by quality control systems that detect and rectify any deviations from the design specifications.After assembly, the gas tank robots undergo rigorous testing and calibration. This phase involves simulating real-world conditions to ensure that the robots can handle gas tanks safely and efficiently. The testing process includes checking the robot's mobility, grip strength, sensor accuracy, and overall performance. Any issues identified during testing are addressed promptly to ensure that the final product meets the highest standards of reliability and safety.The production line also incorporates advanced logistics systems to manage the flow of materials and components. Automated guided vehicles (AGVs) transport parts between different stages of the production process, minimizing human intervention and reducing the risk of errors. Additionally, the production line is equipped with real-time monitoring systems that track the progress of each robot through the manufacturing process, providing valuable data for continuous improvement.Safety is a paramount concern in the production of gas tank robots. The production line is designed with multiple safety features, including emergency stop mechanisms, protective barriers, and advanced sensors that detect and prevent potential hazards. Workers are provided with comprehensive training to operate the equipment safely and effectively.In conclusion, the production line for gas tank robots is a marvel of modern engineering, combining advanced robotics, automation, and precision manufacturing to create highly reliable and efficient robotic systems. This production line not only ensures the highest quality standards but also prioritizes safety and sustainability, making it a benchmark in the field of industrial automation.

产品

分类:

储气罐机器人生产线

-

储气罐机器人生产线

所属分类: 储气罐机器人生产线浏览次数: 78编号:发布时间: 2025-09-08 11:21:33一个储气罐机器人生产线是一个高度专业化的自动化制造系统,旨在生产各种压力容器,包括液化石油气钢瓶、丙烷罐、天然气容器、工业储罐和家用气瓶。这些储罐广泛应用于住宅烹饪、供暖、工业燃料供应、化学加工和能源储存。传统的储气罐生产方式严重依赖手工焊接、切割和检验,容易出现不一致、人为失误和安全风险。随着全球对可靠、安全气体存储的需求不断增长,制造商越来越多地转向自动化。通过整合机器人、数控切割、智能焊接、自动装配和无损检测(NDT),机器人气罐生产线确保高生产率、卓越的焊接质量,并符合国际安全标准。此类生产线不仅提高了效率,还通过减少人体直接接触危险的焊接和切割过程来提高工作场所的安全性。它们适用于不同...

新闻

分类:

暂无搜索结果!

案例

分类:

视频

分类:

暂无搜索结果!

下载

分类:

暂无搜索结果!

招聘

分类:

暂无搜索结果!

推荐产品

暂无搜索结果!

Whatsapp

Whatsapp 电话

电话